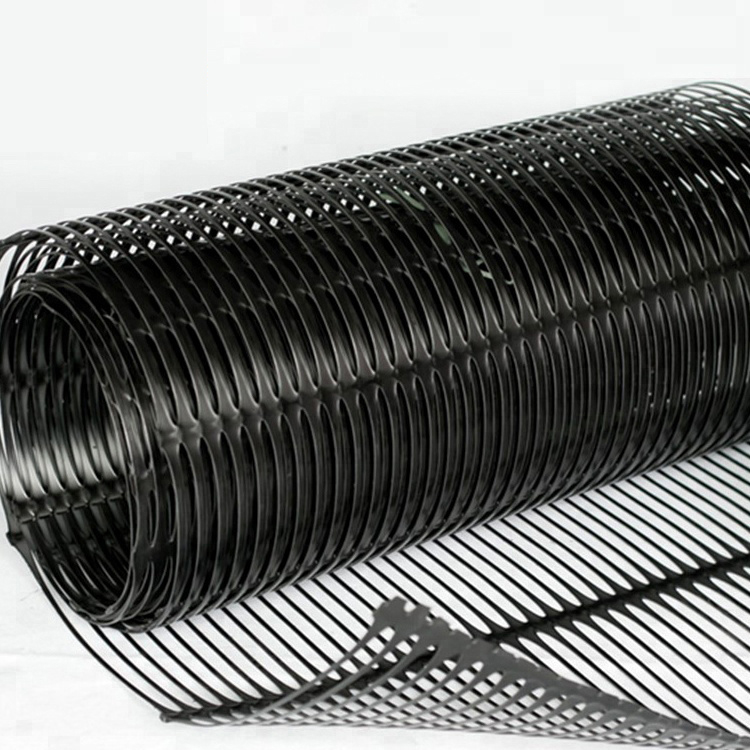

High quality single axis geogrid

Uniaxial geogrid is used to reinforce the soil and increase its load-bearing capacity and tensile strength. It consists of a series of continuously spaced rigid or semi-rigid strips arranged in a grid pattern.

1. Concentrated one-sided strength

2. High tensile strength

3. Certain rigid structure

4. Good water permeability

5. Excellent chemical resistance

Uniaxial geogrid is a geomaterial made from high-strength materials such as polyester or polypropylene. This is a mesh-like material with a rigid structure,

Material: PP/HDPE/PET

Tensile strength: determined by material

Peculiarities:

1. Unidirectional load: Uniaxial geogrid mainly bears tensile force in one direction, has high rigidity and tensile strength, and can effectively increase the bearing capacity of the soil in that direction;

2. Resistance to chemical corrosion: Uniaxial geogrid has undergone special chemical treatment to withstand different water quality and soil conditions, and also has the ability to resist ultraviolet radiation, acid and alkali resistance;

3. Good water permeability: The lattice structure of uniaxial geogrid has certain gaps, which can promote water drainage and soil moisture flow, and has good water permeability;

4. High Load: After certain design and reinforcement, uniaxial geogrid can withstand large heavy loads and provide more stable soil support capabilities.

Application:

Roadbed Strengthening: Uniaxial geogrids can be used in roadway projects such as highways and railways to strengthen and improve the load-bearing capacity of the soil and prevent roadway deformation and settlement. |

|

Slope Protection: Uniaxial geogrids can be used in slope protection projects to improve the landslide resistance of soil and prevent soil erosion and slope failure. |

|

Surface Improvement: Uniaxial geogrids can be used in surface enhancement projects to improve the durability and load-bearing capacity of pavements. |

|

Soil and Water Conservation: Uniaxial geogrids can be used in water and soil conservation projects on river banks, coastal slopes, beaches and other locations to prevent water runoff and soil erosion. |

FREQUENTLY ASKED QUESTIONS

Q: What about the delivery time?

A: Generally 3-15 days after receiving the deposit.

Q: Can you produce products according to customer's requirements?

A: Of course, we are a professional manufacturer, welcome OEM and ODM.